Genetic engineers at the Vienna University of Technology have found a method of producing biofuels from lignocellulose materials, such as wood waste and straw, using fungi.

Genetic engineers at the Vienna University of Technology have found a method of producing biofuels from lignocellulose materials, such as wood waste and straw, using fungi.

The university explained that currently Lignocellulosic waste such as sawdust can only be used to produce biofuel if the long cellulose and xylan chains can be successfully broken down into smaller sugar molecules.

To do this, the researchers said that fungi are used, which by means of a specific chemical signal can be made to produce the necessary enzymes are used. However, because this is very expensive, the university said that it has been investigating the molecular switch that regulates enzyme production in the fungus.

As a result, the institution claimed that it is now possible to manufacture genetically modified fungi which produce the necessary enzymes fully independently, thus makingbiofuel production significantly cheaper.

Recycling waste – not wasting food

According to the university biofuel can be obtained quite easily from starchy plants – but this places fuel production in competition with food production. Manufacturing biofuel from lignocellulose is therefore a preferable option.

“Lignocellulose from wood waste or straw is the world’s most common renewable raw material but, due to its complex structure, it is significantly more difficult to exploit than starch” explained Professor Robert Mach, from the Institute of Chemical Engineering at Vienna University of Technology.

Biological gold

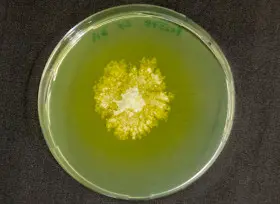

The researchers went on to explain that biofuel manufacturing uses the Trichoderma fungus, which produces enzymes capable of breaking down the cellulose and xylan chains into sugar molecules.

However, the fungus does not always produce these enzymes; production must be stimulated using what is known as an ‘inductor’ (disaccharide sophorose).

In its pure form the university said that sophorose currently has a market value of around €2500 per gram – gold is around €40 per gram.

“The high costs of the chemical inductor are a decisive price driver in biofuel manufacturing”, noted Mach.

Mutations

The university said that it has analysed many different strains of fungus, with varying productivity.

“In one of the strains, a random mutation occurred, which stopped the chemical switch in the fungus from functioning”, explained that professor.

According to the scientists, even without an inductor, this mutated fungus always produces the desired enzymes and, unlike other strains of fungus, does not stop doing so once a high glucose concentration has been reached.

“In these fungi, the molecular switch is always set to enzyme production”, added Christian Derntl, lead author of the recent publication ‘Biotechnology for Biofuels’.

The university claimed that through genetic analysis, it has been possible to identify which gene is required for this behaviour and which protein the gene mutation affects. As a result, it has been possible to induce the same mutation in a targeted fashion in other strains of fungus.

“We have understood the mechanism of this molecular switch and, consequently, many wonderful possibilities are opening up for us”, commented project group leader Astrid Mach-Aigner.

The researchers added that other genetic changes are now being tested in a targeted manner, which may even result in further possibilities for improvement, leading to even more productive fungi, making the production of fuel from lignocellulose more economically attractive.

Free Webcast: Commercial Scale Biofuel from Waste Projects

Solena Fuels, Enerkem and NNFCC share their experience in developing advanced biofuel projects that use waste as a feedstock for renewable aviation and transport fuels…

Fulcrum to Develop Aviation Biofuels from Waste with DoD Grant

Fulcrum BioEnergy, has been awarded a grant from the U.S. Department of Defense to develop renewable ‘drop in’ aviation biofuels.

Fulcrum Secures $175 for Waste to Fuel Gasification Project

Fulcrum BioEnergy has secured commitments and is proceeding toward closing financings totalling $175 million to fund construction of its first waste to biofuels facility.