Medical Waste Plant Ecolog

- Medical and biological waste to electricity and heat

- Fully designed and developed, shovel ready

- 2 technology lines, rotary kiln pyrolysis technology by ATI Industries

- Unique system for flue gases afterburning

- Ceramic filters in the gas cleaning system

- Refrigerators to store hazardous biological waste

- Automatic washing system for containers

- Сrematorium for pets

Details

| Medical and biological waste, ton per year | 24,000 |

| Electricity production, MW | 3 |

| Technology | Rotary kiln |

| Location | Moscow region, Russia |

| Status | Fully developed |

Medical Waste Plant Ecolog designed to process 24,000 ton of medical and biological waste per year. The technology for such type of waste is different from used in municipal solid waste (MSW) plants. Ecolog plant uses rotary kiln as main technology. An exceptional, super-advanced gas cleaning system is implemented to clean flue gases after pyrolysis of the hazardous waste.

Waste to Energy International team completed the design project for the Ecolog plant and received the positive decision of the state construction expertise. Also, our team supported the unique process, when first time in history Moscow bought the land plot for the plant from another subject of the Russian Federation – the Moscow Region. So, we prepared the project to the shovel ready status.

The core technology of the Medical Waste Plant Ecolog

Processing hazardous medical and biological waste requires significantly higher temperatures in the furnace to destroy malignant bacteria and viruses. Rotary kiln technology provides a higher temperature up to 1,100 °C with longer exposition. To compare, incinerator on reciprocating grate processes municipal solid waste at 850 °C with an exposition of 2 seconds.

As the main technology provider, we selected the French company ATI Environment (now ATI Industries). The company has a long history in the production of cremation and special incineration equipment, counted 90 years of experience. With more than 3,000 installations all around the world, ATI Industries keeps a strong leading position in the specialized incineration of hazardous waste. It concentrates on the production of incinerators for medical and biological waste.

Flue gas cleaning system

Medical waste plant Ecolog received in the design project a unique flue gas cleaning system by ATI Industries. First, there are some sophisticated mechanisms to provide efficient afterburning and longer exposition of the waste in the burning zone. This destroys all the biological hazards and provides better flue gas quality even before the cleaning system.

Flue gas cleaning system uses super-advanced ceramic filters, which allow to remove completely such heavy metals as mercury and others from the flue gas. It is especially important because such heavy metal usually occurs in the medical waste in much higher concentrations than in municipal solid waste, for instance.

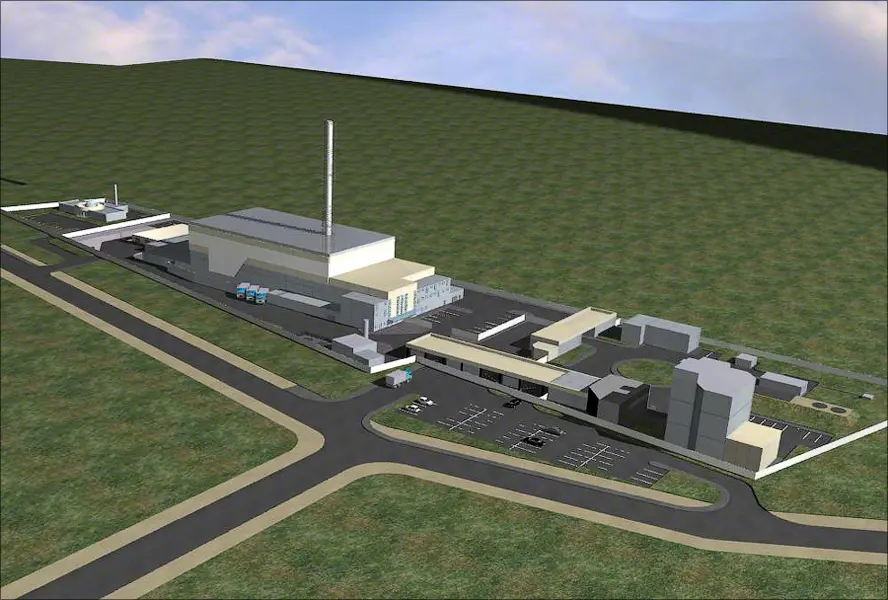

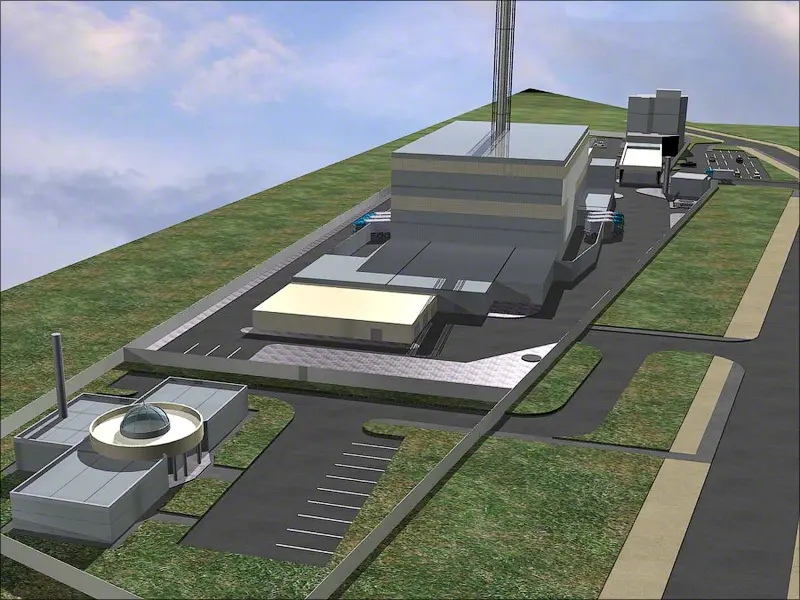

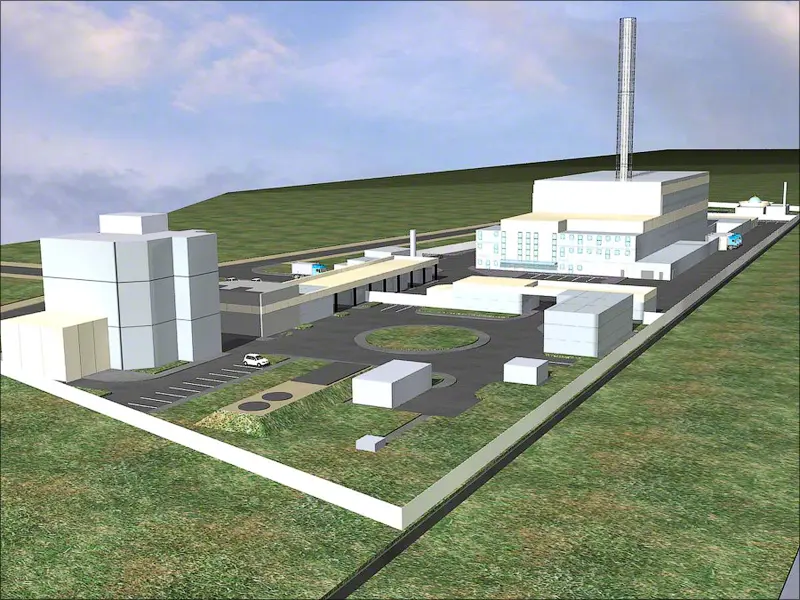

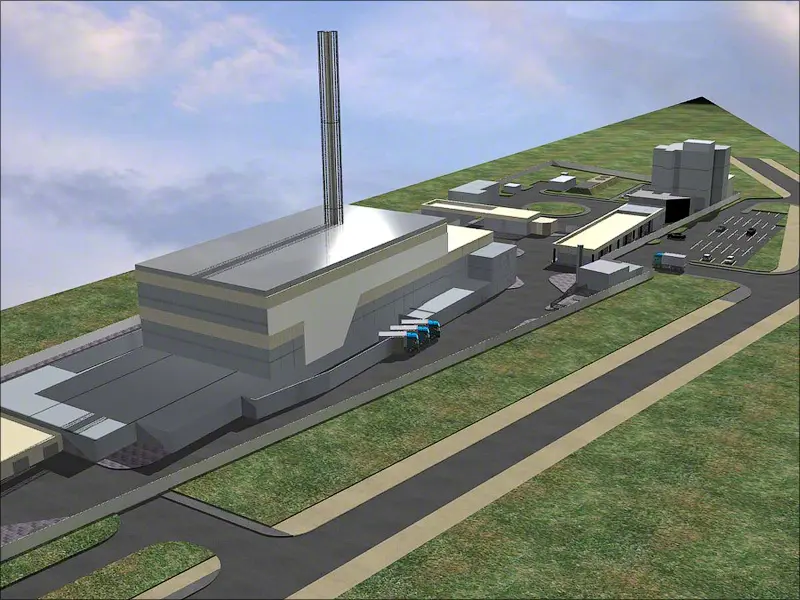

Project Gallery – Medical Waste Plant Ecolog

Proven Expertise in alternative energy Development and Construction

Work With Us

We know how to get energy from the sun, air and waste. Let’s build a better future for everyone, together!

Other WTE projects