MSW Plant 2 – Moscow

- Municipal solid waste to electricity and heat

- The thermal treatment plant in operation

- 2 technology lines, incineration on the grate

- Technology and know-how by CNIM

- Grates by Martin

- Five-stage cleaning system. Effectiveness – 99.8%

- Steam cycle for electricity production

- Electricity and heat feed the city grid

Details

| Municipal solid waste, ton per year | 130,000 |

| Electricity production, MW | 6 |

| Technology | Incineration on grate |

| Location | Moscow, Russia |

| Status | In operation |

Plant №2 in Moscow process 130,000 ton of municipal solid waste (MSW) per year. It uses modern incineration technology with a reciprocating grate and an efficient flue gas cleaning system. To sum up, core technology solutions are provided by top international suppliers: CNIM and Martin.

CNIM – main technology provider of the MSW Plant 2 – Moscow

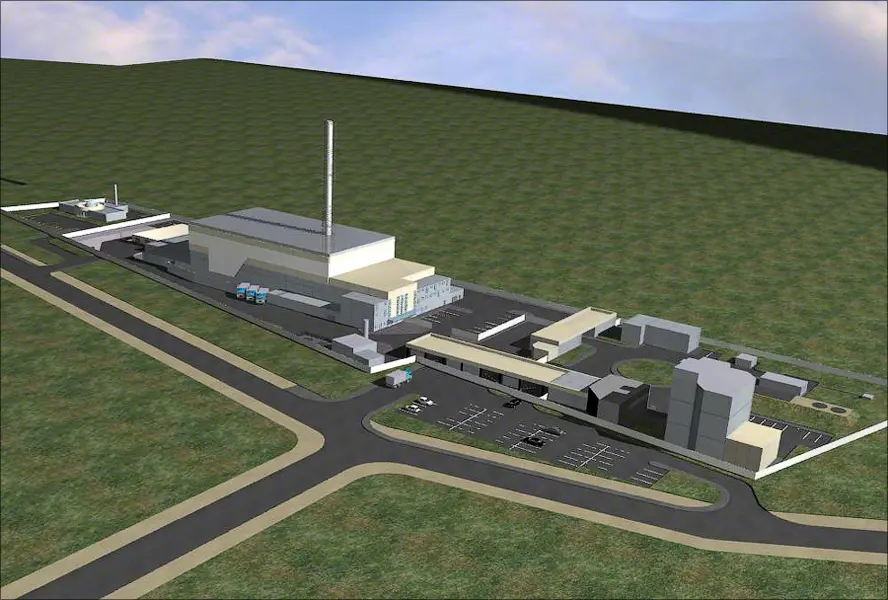

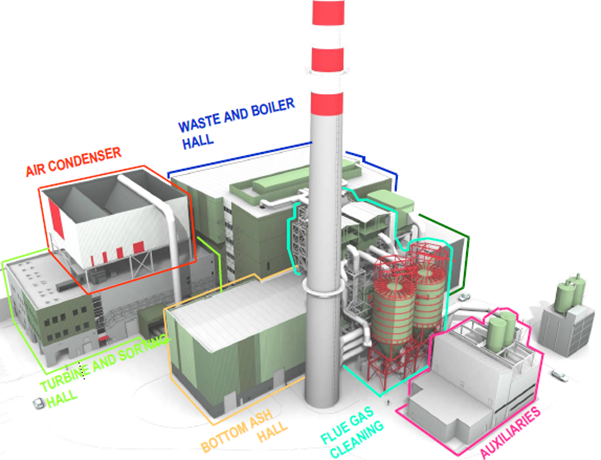

French company CNIM is the absolute leader in the production of incineration equipment and flue gas cleaning systems. With the highest quality of sophisticated waste to energy power plants, CNIM has 55% of the world market. So, in the MSW plant 2 – Moscow, we used main technology equipment by CNIM. The figure below shows the incineration plant outlook.

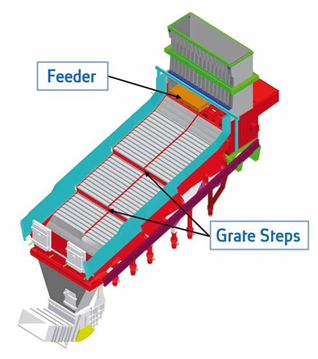

Martin – producer of grates

Bavarian-based company Martin produces the most critical piece of equipment – reciprocating grate. That is to say, this complicated mechanical-hydraulic assembly works at incineration temperatures over 850°C. The diagram below shows the reciprocating grate system, including the feeder’s waste feeding chute and the actual grate.

To optimise the burning of the waste, the grate has thin holes between steps. To clarify, the primary air flows in from the backside of the grate bar through horizontal holes arranged at the front end. The sides of the grate bar are fine finished. The front end of the grate bar is placed on the plane of the previous grate bar, and the rear end is connected with a fixed or mobile frame structure through a specially designed groove. Consequently, a level baffle is arranged at the bottom end of the grate to adjust the thickness of the waste layer.

Each line of the grate is isolated by refractory cast iron pieces with special shapes. Importantly, heat-resistant, corrosion-resistant and wear-resistant castings containing alloy elements (e.g., Cr, Ni and Mo) are adopted for the grate bars and cast-iron pieces for isolation and trace elements such as V and Ti are also added during smelting, which can refine the casting grain and improve the comprehensive mechanical property of the casting, to prolong the service life of the casting.

Therefore, the production of combustion grate requires a very high technical level. A few companies only can maintain the top-level quality of the grate. Above all, the absolute world leader is Martin with 80% of the world market. That is why we used grates by Martin in MSW Plant 2 – Moscow.

Project Gallery – MSW Plant 2 – Moscow

Proven Expertise in alternative energy Development and Construction

Work With Us

We know how to get energy from the sun, air and waste. Let’s build a better future for everyone, together!