MSW Plant 4 – Moscow

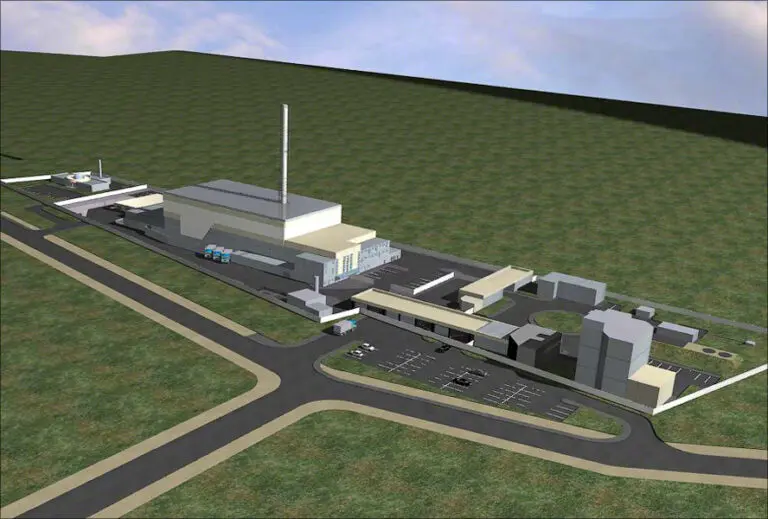

MSW Plant 4 – Moscow process 250,000 ton of municipal solid waste (MSW) per year. The plant core technology is a fluidized bed.

MSW Plant 4 – Moscow process 250,000 ton of municipal solid waste (MSW) per year. The plant core technology is a fluidized bed.

MSW Plant 2 – Moscow processes 130,000 ton of MSW per year. Core technology solutions are by top international suppliers: CNIM and Martin.

Medical Waste Plant Ecolog designed to process 24,000 ton of medical and biological waste per year. The plant uses rotary kiln technology.

Industrial Waste Plant Ugreshka designed to process 15,000 ton of hazardous industrial waste per year. The plant uses rotary kiln technology.