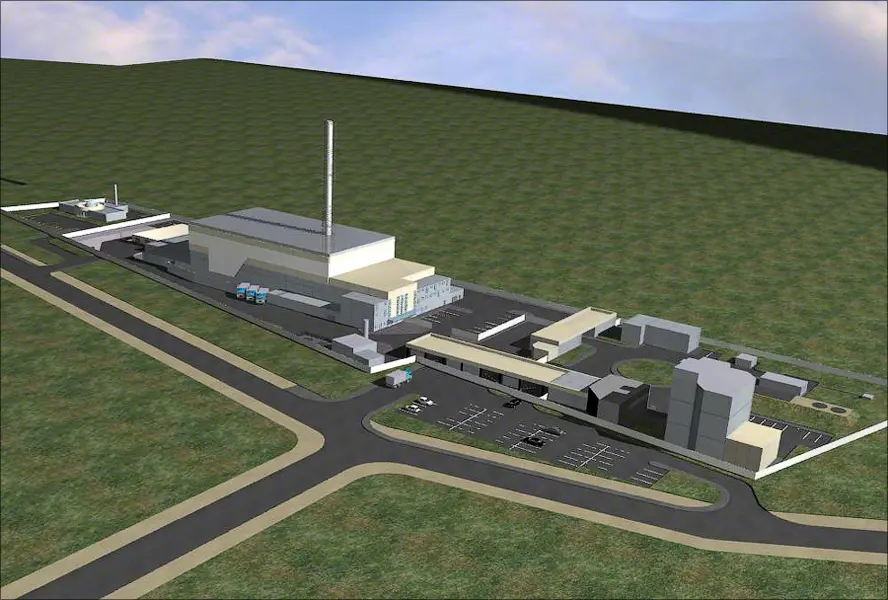

The main focus of the WTEI activity is the waste to energy plant development using modern technologies.

Using an uncommon background in the real construction and commissioning of waste-to-energy plants, our team provides the development. We deliver all stages of the development process, from green grass to commissioning. Having in our portfolio constructed and fully designed plants, our team performed as developers in more than a hundred projects. We at Waste to Energy International (WTEI) have experience in incineration, pyrolysis, high-temperature pyrolysis, sorting and landfilling.

Turn garbage into clean energy with our state-of-the-art waste to energy plant

Our experience covers working with municipal solid waste (MSW) and hazardous industrial and medical waste. Technologies suitable for these types of waste are different and are subject to proper selection during the feasibility study. Long-term professional relationships with the world top technology providers allow us to provide a proper estimation of the project efficiency. Such estimation is based on the given type of waste and its characteristics.

Waste to energy plant development

The waste to energy plant development starts from identifying stakeholders of the project. Commercially, the waste to energy project has two flows of revenue:

- gate (tipping) fee;

- sale of the main product.

The main product could be electricity, heat or synthetic fuel. Consequently, it is important to identify the governmental structures as the waste supplier and the off-taker. Two agreements are the cornerstone documents for the project: the Concession Agreement and the PPA (Power Purchase Agreement). The municipality/governate is the party to sign the Concession Agreement. A state-owned grid company proposes and signs the Power Purchase Agreement.

WTE Project Structure

Usually, there are 3 developers:

- the technical developer (WTEI);

- the investor (our long-term partner);

- a local developer.

Waste to Energy International (WTEI) provides comprehensive technical and economic analysis, performs market reviews relevant to the project. Further, we analyse site location, selects technology and certain technology provider, executes the technical part of the feasibility study. We maintain economic calculations by our proprietary financial model, having more than 50 parameters.

Our investment partner executes the financial part of the feasibility study and raises 100% investment needed for the project. Fundraising takes backgrounding from our technical and economic evaluations. This is the reason why our long-term cooperation led to creating a group of companies.

The local developer is responsible for signing the Concession Agreement and the Power Purchase Agreement. His responsibility is getting approvals and maintaining relationships with the governmental structures.

Preparation for the development

Importantly, before launching the feasibility study, we create a detailed Request for Information (RFI). The document counts more than 70 questions to be clarified together with the local developer. RFI includes questions on the geographical location, local regulations, climatic and seismic conditions. We also investigate available pipelines, transportation links, soil stability, underground water resources, ecology requirements and so on. These answers comprise a solid background for making decisions on the technology.

Waste to energy plant is a facility accepting organic waste and producing energy from it. Incineration aimed to produce electricity and heat. The prevalent number of waste to energy plants existing in the world are incinerators. They use steam cycle and turbine to produce the electricity and heat. All modern plants have a sophisticated gas cleaning system conforming to the strictest air pollution standards. Pyrolysis technology can convert the waste to high-quality fuel like diesel oil or DME (dimethyl ether).

The economic efficiency of the plant depends on the selected output. We can construct plants providing any possible output: electricity, heat, heating oil, diesel or DME (dimethyl ether). Output type depends, however, on the feedstock. So, the most efficient approach is to produce electricity from MSW and a kind of synthetic fuel from high-energy waste. Plastics and tyres are good examples of high energy waste.

Waste to energy plant development stages

The first stage of the development process for a WTE plant is the preparation of the feasibility study. The feasibility study represents a thorough document comprising four aspects: market review, technical feasibility, commercial feasibility and financial feasibility. During the market review, our team compares the best available technologies and proposes a fitting selection for the project. We take into account technology’s environmental protection characteristics, global availability, price of the equipment. Additionally, we count the cost of further maintenance and consider the local conditions.

On the technical feasibility step, our experts conduct extensive research utilizing location-specific data. These data include lab evaluation of the regional waste composition aimed at evaluating the energy result of the future plant. The commercial feasibility study includes drafting the Concession Agreement and Power Purchase Agreement. As noted above, these documents are key to the project. WTEI finalizes the feasibility study with the financial feasibility part, where our experts update the baseline financial model. Calculations produce financial indicators like IRR based on the parameters as CAPEX, OPEX, annual interest rate, debt/equity ratio etc.

Defining construction partners and providing project supervision

Our feasibility study focuses on bankability, that is why we select a worldwide-known, proven technology provider. WTEI cooperates with equipment producers and EPC providers with a multi-billion dollar annual turnover. During the feasibility study, we communicate with a selected one and receive a firm commercial proposal including CAPEX and OPEX of the planned plant. The usage of such real data bears weight to our financial model and increases the confidence of banks.

Upon commencement of funding, WTEI starts the design project and deploys the TIO (Technical Interface Office) on site. The role of the TIO is to support and supervise the execution of the project, protecting the interests of the shareholders. Finally, TIO supports the commissioning of the plant, which happens after 2-3 years of the construction period.

Cost of building a waste to energy plant

The cost of building a waste to energy plant is discussed very often. To reduce the spread of rumours on this topic, we wrote an article which is quite popular and we strongly advise you to read it: “Cost of incineration plant”. It contains a reference to the scientific investigation, a formula, diagram and a cost calculator. Otherwise, if you know how it works, here’s our waste to energy plant cost calculator.

Usually, the operating and maintenance cost of a waste to energy plants can be estimated at 3%-7% from plant hard costs (CAPEX).

The answer depends on the type of waste, its chemical composition and moisture, which has a heavy influence on plant efficiency. Also, we should take into consideration the technology applied and the total cost of the plant. If we talk about municipal solid waste and incineration in Europe, so waste-to-energy projects there require feed-in-tariff (FIT) and tipping fee (TF).

FIT for major countries is 0.12 – 0.14 USD per kWh.

Additionally, a tipping fee is required: 80 – 100 USD per ton.

What to think about when designing a WTE plant

The key factors influencing the waste to energy plant design, and the development of waste to energy plants as a whole, are:

- Waste type (municipal solid waste, tyres, plastics, wood chips, hazardous industrial or medical waste). Different types of waste require different technologies.

- Amount of waste (ton per annum). The tonnage heavily depends on the technology selection due to scalability and unit price.

- Desired/possible output (electricity, heat, synthetic fuel of different types). Some technologies are better at producing electricity, some fit to produce synthetic gas and fuel from it.

- Plant location and availability of electric, heat, water pipelines. The absence of an electricity grid connection prevents usage of the incinerators and the developer should select a less efficient technology for the municipal solid waste, for example.

- Local legal and ecological requirements. In some countries there are limitations to use a certain technology and this circumstance may turn the whole development process to a different way.

- Availability of underground water resources needed for incineration steam cycle. We had a case that lack of water resources demanded usage of pyrolysis technology, less efficient with the municipal solid waste.

- Global accessibility and mass confirmation of the technology selected. Investors and banks are very cautious about accepting a new, not well-proven technology.

- The experience and credibility of the EPC company selected. The financial strength and performance bonds provided by the EPC company is a very important factor of project sustainability.

Waste to energy plant business plan

Waste to energy business plan should consider and estimate the commercial and financial feasibility of the project, taking into account all the risks. Such a plan shall be based on the feasibility study and include all the technical, economic, financial assessments performed by a professional company with the proven experience in the industry. You can find a detailed explanation of the feasibility study above in this article.

The business plan for waste to energy plant is some essential amendment to the feasibility study findings, containing a more detailed description of the project stakeholders, SPV (Special Project Vehicle) participation, requirements to the O&M (operating and maintenance) company, configuration of the project steering committee and financial projections taken from the feasibility study.

This is to mention, that many financial institutions and private equity investors do not require a business plan at all, accepting the feasibility study as a founding document for the development of waste to energy plants.

FAQ

The major by-product of a waste to energy plant is the ash, which can be used in construction. The incineration plant produces two types of waste: bottom ash from the furnace and so-called fly ash, from gas cleaning system filters. Whilst bottom ash can be used in the construction of roads or in the production of bricks, the fly ash is hazardous and must be buried in landfills. Fortunately, fly ash comprises only 2-3% of the initial waste tonnage. Bottom ash output usually equals 10-15% of the initial waste tonnage.

Waste-to-energy plants are similar to the traditional power stations (coal or gas) in many aspects. However, additional training is required for power engineers to get familiar with waste management, maintaining incineration of such bad and unstable fuel as the waste. Environmental protection provided by the sophisticated flue gas cleaning system is another system you need to get familiar with.

Wastes that are generally burned in a waste to energy plant include municipal solid waste (MSW), human sludge, hazardous industrial, medical and biological waste. The biggest number of installations has incineration of the MSW with the production of the electricity and heat – 2,500 installations across the world, including almost 500 in Europe.

Plants we built

Waste to Energy International (WTEI) has exceptional experience in the real construction of waste to energy plants in the megapolis. We dealt with waste to energy plants converting municipal solid waste to electricity and heat (and those plants are still under operation). We fully designed and passed expertise, bringing to the ready to build stage, a hazardous medical and biological waste plant and the hazardous industrial waste plant. Additionally, we participated in many projects focused on the processing of tyres, plastics, sludge, manure with pyrolysis technology.

MSW Plant 4 – Moscow

MSW Plant 2 – Moscow

Medical Waste Plant Ecolog

Our Partners

Proven Expertise in alternative energy Development and Construction

Work With Us

We know how to get energy from the sun, air and waste. Let’s build a better future for everyone, together!