In October last year, an Extraordinary General Meeting approved a move that has seen Finnish process control and equipment manufacturer, Metso, split into two. From January this year the company demerged, separating its pulp, paper and power business to form a new company, Valmet Corporation. The company’s mining, construction and automation business will continue as Metso.

In October last year, an Extraordinary General Meeting approved a move that has seen Finnish process control and equipment manufacturer, Metso, split into two. From January this year the company demerged, separating its pulp, paper and power business to form a new company, Valmet Corporation. The company’s mining, construction and automation business will continue as Metso.

“Metso itself was created by a merger between Valmet and Rauma (in July 1999). Since then we’ve been buying companies both to strengthen our minerals business and to strengthen our pulp paper and power business. Both of these sectors are now big enough to stand on their own two feet,” Pasi Laine president & CEO of Valmet tells WMW.

Following the demerger, Valmet is focused on technology and services for industries around the world that use bio-based raw materials. The company is organised around three business lines – Services, Pulp and Energy and Paper.

“The story of Valmet is that our business is based on renewable raw materials, whether it’s waste, wood or recycled paper,” explains Laine.

“We make paper and board machines which can make recycled paper and we make pulp mills by which our customers can make pulp for paper making, and we make boilers with which our customers can generate heat and electricity.”

Advanced technologies

Valmet’s energy offering consists of complete biomass heat and power boiler islands and rebuilds including fuel handling, boiler, auxiliary equipment, automation and air quality control. However, Laine is confident that the company’s innovation in developing new products will also be a major driver for its future growth.

“We want to have new technologies such as lignin separation technology which produces something which can be used as a biofuel. We want to develop new technologies which allow our customers to use renewable raw materials, including waste, to produce new kinds of products,” he says.

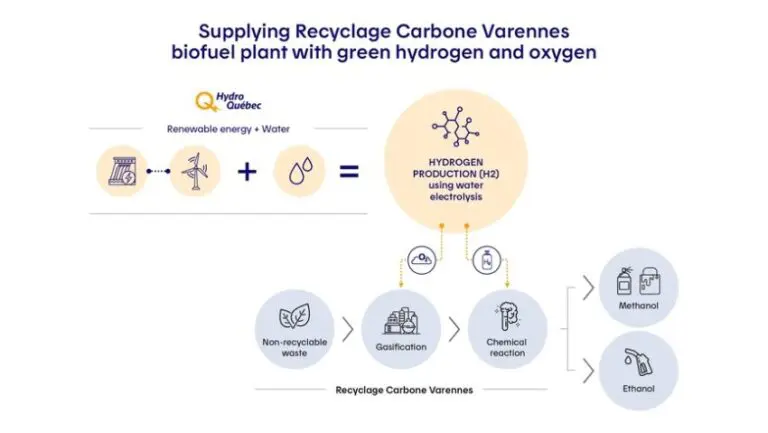

The company has developed a number of new biomass conversion technologies with which it aims to open new market opportunities. The newly developed technologies include biowaste gasification, fast pyrolysis to produce bio-oil from forest residues, lignin separation technology for the production of biofuel from black liquor and second generation bioethanol technology – among others.

Laine explains that waste gasification technology has been a particular interest for the company. Prior to the demerger, in 2012 Metso supplied its first full scale gasification plant to the city of Lahti. The 140 MW combined heat and power facility gasifies Solid Recovered Fuel (SRF) to produce a syngas which is cooled and cleaned, and then combusted in the boiler.

The gasification plant was constructed as part of an existing coal fired power plant. For its part in the Lahti project Metso/Valmet installed the fuel handling system, a large-scale dryer and a circulating fluidised bed gasifier. The company also carried out modification work on the existing coal boiler and a Metso DNA automation system. Syngas produced by the gasifier is combusted along with coal in the existing coal boiler, replacing around half of the coal previously combusted at the facility.

Fast Pyrolysis

Another of the advanced biomass conversion technologies that Valmet has successfully deployed on an industrial scale is its fast pyrolysis system which is capable of producing a heavy oil, dubbed bio-oil, from forest residues and wastes. The bio-oil can replace heavy fuel oil in heat and power generation. The company says that with additional technological development it could be further refined to into transportation fuel, thus potentially opening up a large new market.

The pyrolysis technology is at the heart of a facility recently commissioned by Finnish sustainable energy company – Fortum – in Joensuu, Finland. The plant is expected to produce some 50,000 tonnes per year of bio-oil and will increase the Fortum’s wood use in energy production in Joensuu from 300,000 to 450, 000 solid m3/yr.

“It’s a plant where we make a replacement for heavy oil from forest residues,” explains Lain. “We have a combined heat and power plant where there’s a boiler, and then next to the boiler we built a pyrolysis plant. We use forest residue as a feedstock and it uses sand from the boiler to heat the residues up until it becomes gaseous and we end up with pyrolysis oil which in some applications can be used as a replacement for heavy oils.”

Lignin Separation

Valmet has also developed a lignin recovery technology, LignoBoost, which separates lignin from black liquor (the used cooking liquid from a pulp mill) which it says removes a bottleneck from the recovery boiler and boosts production efficiency. The recovered lignin can be utilised as a renewable fuel to replace fossil fuels and also as a new bio-based raw material for many industries. Potential new products could include biofuels, activated carbon, low cost carbon fibres and resins.

“We use different types of filters and other technologies to filter the lignin out of the black liquor and the rest of the liquor is burned in the recovery boiler. The lignin is dried and can be used as a replacement for fossil fuels or used in other applications,” explains the CEO.

The company supplied its first commercial scale lignin separation plant to the pulp and paper company Domtar in Plymouth, North Carolina back in 2012, and has recently entered into an agreement to supply the system to Helsinki based paper, packaging and wood products manufacturer Stora Enso for its new €32 million biorefinery project.

According to Stora Enso, once operational in early 2015, the biorefinery at its Sunila Mill will reduce the CO2emissions by replacing up to 90% of the natural gas currently used for energy with lignin extracted from the black liquor. The company says that this will be the first step towards a new business selling lignin to external customers and will enable specialty chemical and high-tech material customers to replace fossil based raw materials.

“The first applications will be in, for example, the building, construction and automotive sectors, where lignin offers sustainable alternatives for phenols in plywood glues and other wood-based panels, and polyols used in foams. Other applications are also under development,” comments Juan Bueno, executive vice president at Stora Enso Biomaterials Division.

Bioethanol

Both the EU and the U.S. have mandates and incentives to significantly increase production and consumption of bioethanol. On the back of this there is already significant investment being made in second generation bioethanol facilities, and it’s an area where Laine says Velmet can bring considerable expertise.

“We have got a number of orders for the pre-treatment equipment for second generation ethanol plants. We are not building the whole plant, we are installing the pre-treatment equipment before enzymatic treatment and before fermentation takes place.

“We have very good processes and we have utilised the knowledge that we have gained in the pulp industry. We have been using that technology to prepare material for pulp plants for decades and now we can use that experience in second generation ethanol plants,” adds Laine.

Conclusions

In a world dominated by globalisation, where we have become used to giant corporations merging with each other to form even larger more complex organisations, it may seem a little unusual for a major manufacturer to demerge. But if the old adage of ‘innovate or die’ is to be believed, there are some obvious advantages for each of the demerged companies.

While both Valmet and Metso will remain major multi-billion Euro businesses, their freshly sharpened focus can only be good for the industries they serve.

When it comes to biowaste, many innovations have shown potential – few have actually been proven on a commercial scale. Having already deployed a number of its new technologies in major facilities, Valmet would seem to be in a strong position in its chosen markets.

If Laine is right, and the demerger allows Valmet to better focus on its core industries, the company could well be about to carve out a number of all new markets for itself.