Waste to Energy Technologies Overview aims to provide a concise description of the available technologies on the market. Every technology mentioned has its own benefits, disadvantages and area of applicability. We as Waste to Energy International (WTEI) offer many sustainable solutions for thermal residue utilization. Thermal treatment significantly reduces waste disposal on landfill sites such as municipal or industrial waste and sludge, and medical or industrial hazardous waste. The generated energy output results in a new revenue source that has economic benefits for the local community and environmental benefits in cleaner air, water, and soil.

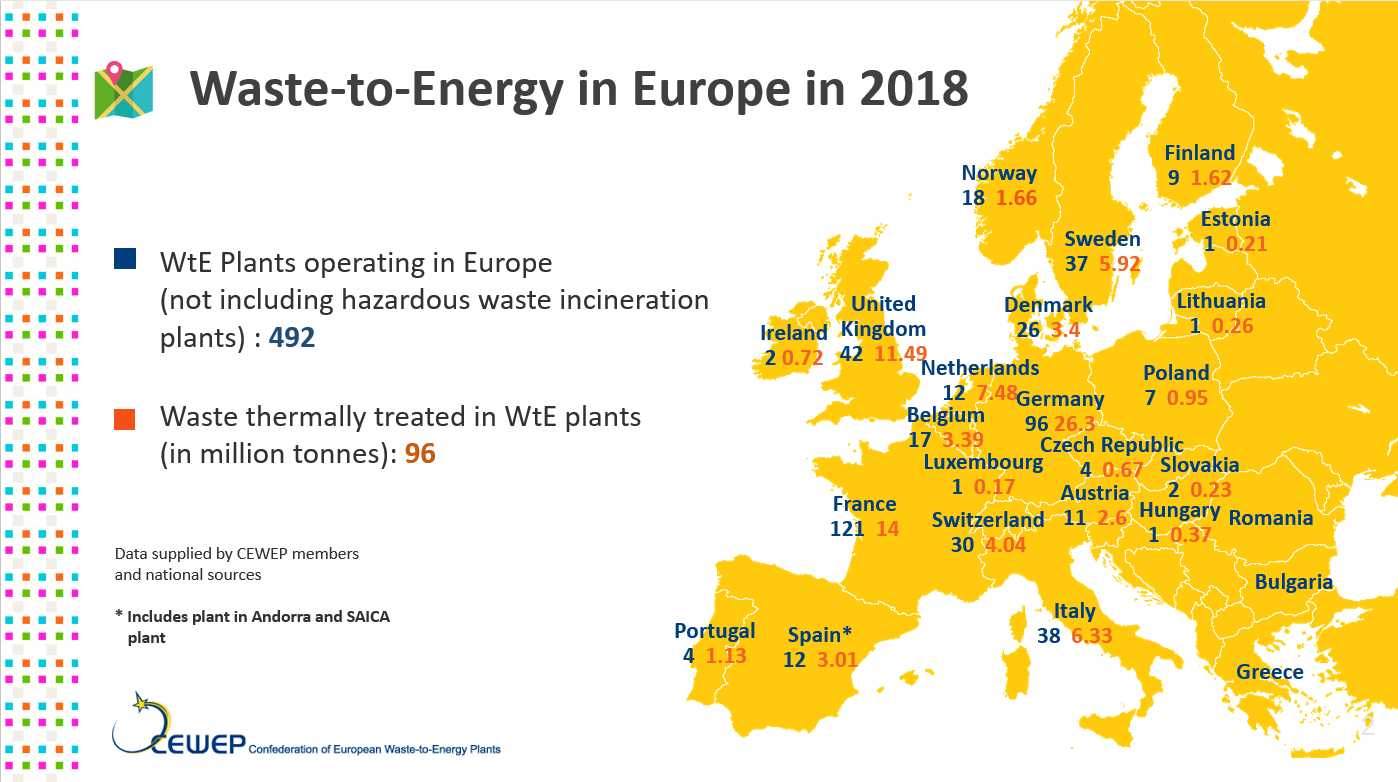

There are more than 2500 waste-to-energy plants in the world, including almost 500 in Europe.

Below is the list of main technologies applicable to get energy from waste. Almost all of them are implemented in our projects.

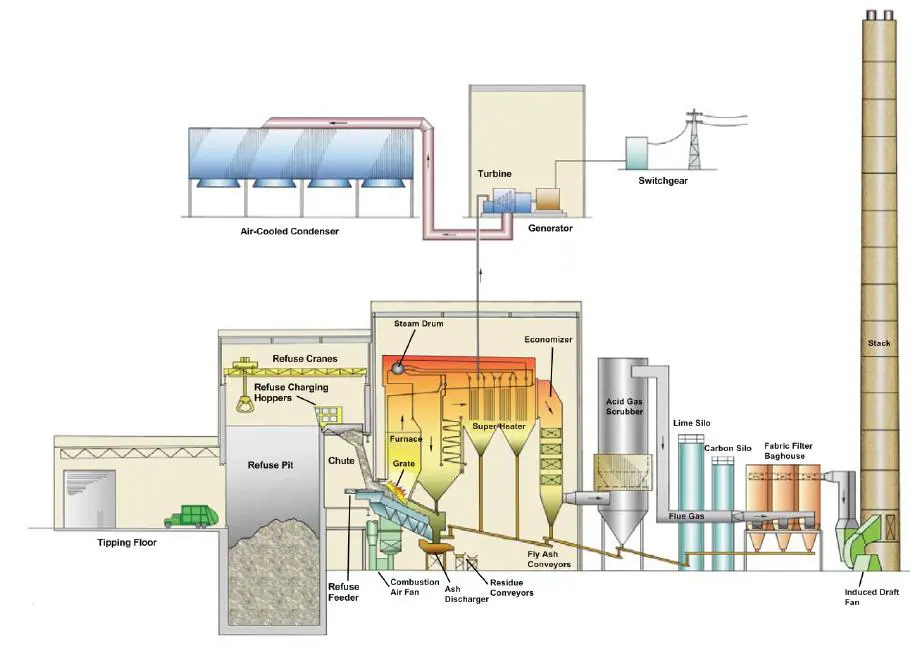

Thermal Treatment on Grate

World widespread, prevalent technology. Very reliable due to accumulated big experience of production and operating of such plants. Many producers are manufacturing sophisticated equipment to process the waste on the grate and produce electricity and heat. After cardinal improvements of technology of flue gas cleaning, now incinerators are recognized as clean technologies, which was approved in 2005 even by the statement of German Federal Minister for the Environment, Nature Conservation and Nuclear Safety, member of The Greens party.

The industry worldwide leaders in incineration are our partners CNIM and Martin. They have 55% and 80% of the world market, respectively.

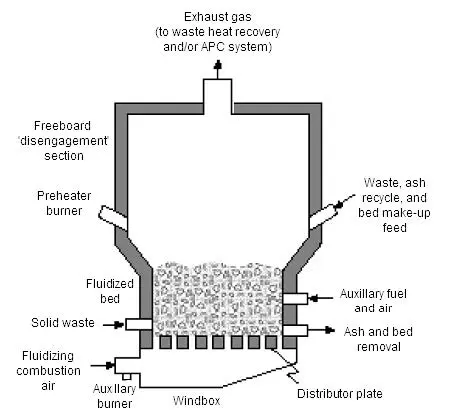

Fluidized Bed Technology

The fluidized bed is also one of the principal waste-to-energy technologies. There are static or circulating variants of the bed. The technology is mainly used to process sludge or municipal solid waste. It has high efficiency of processing and low residual values. The fluidized bed technology always includes energy recovery and flue gas treatment. The flue gas pollution level is far below regulatory requirements.

In our projects, we partnered with a European industry leader Hölter (now Air Liquide).

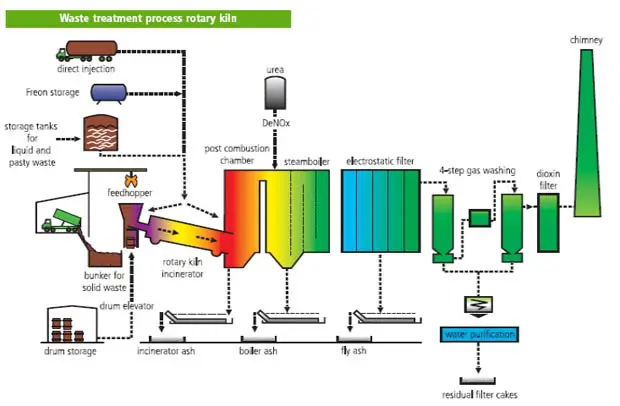

Rotary Kiln

Used to process hazardous medical, biological and industrial waste. Higher temperatures allow controlling the full destruction of viruses and microbes, low oxygen intake guarantees low emission values.

We have prepared shovel ready projects with such rotary kiln producers as ATI Industries (3,000+ installations) and Envirotherm.

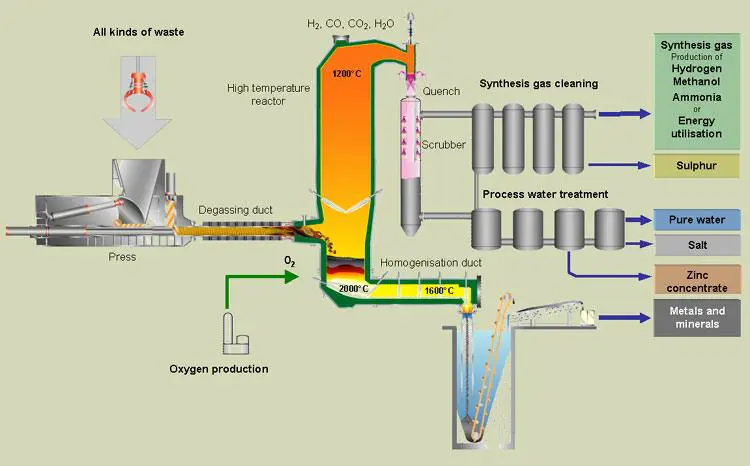

Gasification

Is also well-known technology, having a long history on the market. But it is not so wide implemented as processing on the grate, because of several problems, including oxidation of hydrocarbons, production of high levels of CO2, production of pollutants during gasification and low calorific value of produced synthetic gas.

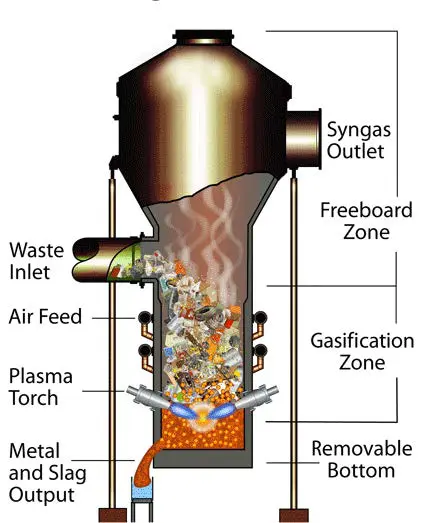

Plasma Arc Gasification

Technologists use plasma arc gasification to process a specific group of waste: very hazardous and radioactive. Very expensive, consume a lot of energy for the process and has some problems. A low level of net energy does not allow to say about energy effectiveness. High temperatures of 9600°C are good for processing hazardous waste but are not manageable.

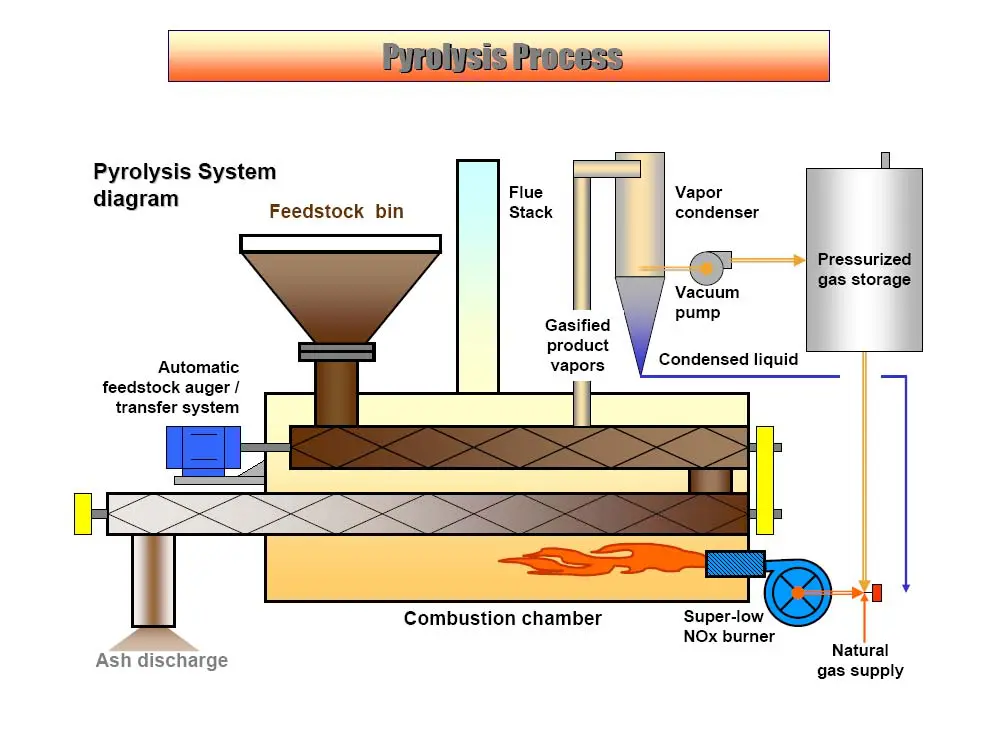

Pyrolysis

German engineers invented pyrolysis many decades ago and now the chemical industry uses it widely. However, the waste application started relatively recently. Technology has many benefits as minimum oxidation of the waste, no production of pollutants, high level of synthetic gas production, high level of calorific values for this gas, clean gas production which can be used in Genset. Seems to be the most ecologically clean, simple and modular modern technology of waste utilization. The only problem – it is not well known on the market.

WTEI puts special attention on this technology and tries to implement it in every new project. WTEI has an agreement with the owner for marketing and selling this patented pyrolysis technology in different regions of the world, including Europe.

We are proud to cooperate with our clients to select and implement the technology, most applicable for your project. Our team of highly experienced engineers can provide the feasibility study, investments and construction supervision.

Supported Waste Categories

Technologies listed above in the Waste to Energy Technologies Overview can accept waste material from the following supported waste categories.

- All domestic (municipal solid) waste

- Paper, cardboard & packaging materials, while fully supporting the recycling of all paper products

- Plastics of all categories and textiles

- Rubber, tires etc.

- Sewage sludge and farm waste (up to 80% moisture content)

- Animal meat processing waste

- General food processing waste

- Restaurant waste

- Construction waste: wood, shingles

- Oil and crude oil contaminated soils

Waste to Energy FAQ

Waste to energy plant is a facility accepting organic waste and producing electricity and heat from it. Pyrolysis technology can convert the waste to high-quality fuel like diesel oil or DME (dimethyl ether). The prevalent number of waste to energy plants existing in the world are incinerators. They use steam cycle and turbine to produce the electricity. All modern plants have a sophisticated gas cleaning system conforming to the strictest air pollution standards.

The answer depends on the type of waste, its chemical composition and moisture, which has a heavy influence on plant efficiency. Also, we should take into consideration the technology applied and the total cost of the plant. If we talk about municipal solid waste and incineration in Europe, so waste-to-energy projects there require feed-in-tariff (FIT) and tipping fee (TF).

FIT for major countries is 0.12 – 0.14 USD per kWh.

Additionally, tipping fee is required: 80 – 100 USD per ton.

Hello Igor, what is the possibility of private/public partnership wiyh your company in a Build & Operate WTE plant Venture in the Federal Capital Territory, Abuja & Enugu State of Nigeria?

Thank you for contacting us. We have answered by email.

Hello Igor we have a plant in eastern,Pa in the USA we are a recycling plant

And in 2023 we spent 1.4 million dollars in landfill cost and we are interested

In turning are waste into energy if it is financially viable please let us know if

You can assist on working with us on this project

Warmest Regards

Jack Amoruso

Thank you, Jack,

I have answered via email.

Dear sir and madam

I am from Mongolia. We are really interested in your waste treatment technology, specifically by the gasification of all kind of wastes. So please let us know more about the technologies.

please send me by my email.

thank you

Dear Batu Lkhanaa,

You can find additional materials on our website: Why incineration?, Cost of incineration plant, Pyrolysis, etc.

Good evening sir,

I have read about the benefits of WtE. I live in Zambia and I can assure you that as a country, Zambia is ripe for this technology because we have a lot of raw material (waste) for this to work. Infact, as a country, we are grappling with waste management such that our land fill is almost full beyond redemption. Our government has introduced a new ministry called Ministry of Green Economy and am very sure this ministry will give us support when we start the project of WtE. My interest is in the generation of electricity from this technology.

How can we be assisted to set up this WtE project?

Dear Henry,

Thank you for your message. We have answered by email.

Hi Mr Gergel

We are a investor company and we have a licence for Wte in Turkey close to Istanbul.I would like to talk you in detail about finance and equipment.

Best Regards

Thank you, Mr Terzioğlu,

I have answered by email.

very interesting information, I am curently working in preparing to have some small WTE plants in Abudhabi

regards

Dear Mr Alali,

Thank you for your message. I have answered you by email.

Good day…. I am very much interested on waste to energy treatment plant. Any assistance or studying programs that I can enrol with.

We do not provide any studying programs but have a lot of educational articles and blog posts on our website.

Stay with us to have the latest industry news!

Greetings,

There is an urgent Waste to Energy Project to be undertaken in Nairobi, Kenya. Kindly get in touch as soon as possible via the email below.

Dear Mr Mulwa,

Thank you for contacting us. We have answered via email.

Is it good for Panama to have a WTE PLANT? The capital of the country Panama City, Panama ; generete 3000 tons per day alone. Hope to hear from you soon, regards. J

A waste-to-energy plant is a good solution for any country. We can bring investments and technology to Central America.

For more information, please contact us by email. Thank you.

Good day Mr. Gergel,

I am interested in engaging your company for waste to energy contracts in partnership with certain state governments in Nigeria. I await your positive feedback on this. Thank you.

Thank you, Mr. Ivhurie. We will answer you by email.