Cupertino, California based renewable fuels and chemicals specialist, Aemetis (otcqb:AMTX) has been has been granted approval to produce ethanol from separated food waste at its 55 million gallon (208 million litre) per year renewable ethanol plant in Keyes, California by the US Environmental Protection Agency (EPA)

The company said that the EPA approval includes D5 Renewable Identification Number (RIN) generation for separated food waste feedstock used at the plant, allowing it to qualify its ethanol as Advanced Biofuels through the processing of certain food/beverage waste streams into ethanol.

Aemetis explained that RINs are numerical codes created with every gallon of biofuel domestically produced or imported into the US, and play the dual role of a renewable fuel credit to incentivise renewable fuel use, and a tracking mechanism to monitor the production, movement and blending of biofuels.

The company also received approval to produce D5 ethanol using grain sorghum and biogas with the plant’s existing Combined Heat & Power (CHP) system.

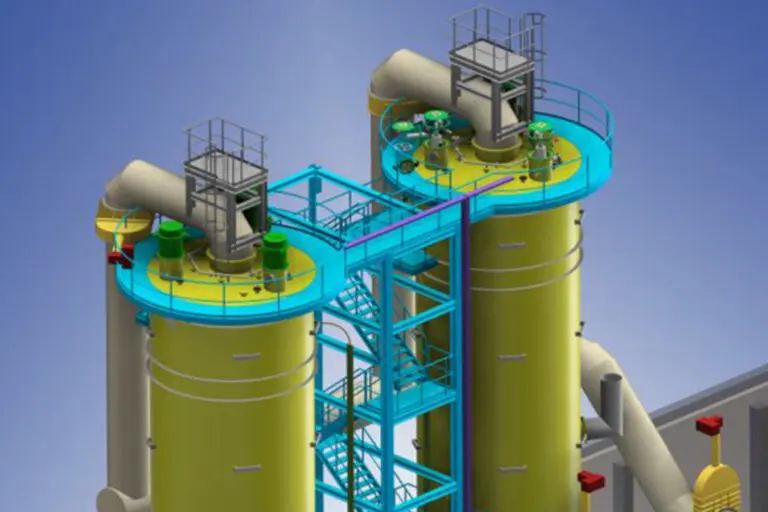

According to the renewable fuel specialist, the flexible feedstock design of its Keyes plant (pictured) allowsit to utilise both traditional and advanced feedstocks and energy sources to produce renewable fuels, including higher-value, advanced biofuels to help meet the Advanced Biofuels requirement of the Renewable Fuels Standard (RFS).

Until now, the D5 Advanced Biofuels RIN portion of the RFS has been mostly met by imported Brazilian sugarcane ethanol or by substituting D4 biodiesel RINs due to a lack of advanced ethanol production, the company said.

Aemetis also operates a 50 million gallon facility in Kakinada, India which was built in 2008 to use the stearine waste product from the edible oils industry to produce non-food biodiesel and refined glycerin for pharmaceutical and industrial customers.

According to Eric McAfee, chairman and CEO of Aemetis, combined, the company’s US and Indian facilities generated some $190 million of revenue in 2012.

“After several years of work and significant investment, today the Aemetis Keyes plant was approved by the EPA as the first corn ethanol plant in the US to be converted to use lower-carbon feedstocks and renewable energy sources to produce Advanced Biofuels and earn valuable D5 RINs,” commented McAfee.

Read More

Waste plastic to oil recycling firm to close operations in Ontario

Ontario, Canada based waste to oil specialist JBI will close operations at its recycling facility in Ontario over the next few weeks as a result of cost cutting measures…

90,000 TPA Dry Anaerobic Digestion Biogas Plant in San Jose uses Special Concrete

Specially engineered concrete supplied by Central Concrete is being used in the construction of Zero Waste Energy’s 90,000 ton per year dry AD biogas facility in San Jose, California.

17,000 TPA Anaerobic Digestion Biogas Plant at Michigan State University

Michigan State University has operand a 17,000 ton per year anaerobic digester that will produce biogas from the co-digestion of farm and food waste on its campus.